friction test mos2|atomically thin mos 2 : discounter Sliding tests of MoS 2 showed ultralow friction in N 2 but high friction in humid air. •. MoS 2 transfer layers were parallel reoriented with formation of MoO 3 embedded. •. DFT . WEBNo bairro Angelim, em Presidente Dutra (MA), uma jovem de aproximadamente 14 anos, identificada como Emanuelly Silva e Silva, cometeu um ato trágico ao se jogar na frente .

{plog:ftitle_list}

webCapítulo 205, sexta-feira, 16 de fevereiro. Capítulo 204, quinta-feira, 15 de fevereiro. Capítulo 203, quarta-feira, 14 de fevereiro. Capítulo 202, terça-feira, 13 de fevereiro. .

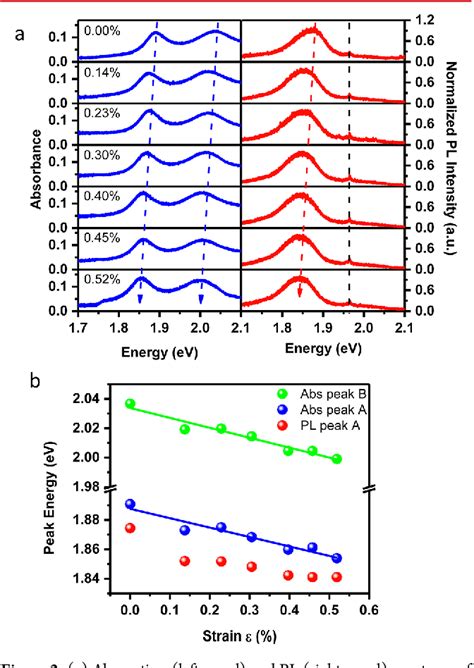

The electronic contribution to energy dissipation of friction on atomically thin MoS2 was confirmed and regulated through tuning the strength of the electron-phonon coupling.We would like to show you a description here but the site won’t allow us. Sliding tests of MoS 2 showed ultralow friction in N 2 but high friction in humid air. •. MoS 2 transfer layers were parallel reoriented with formation of MoO 3 embedded. •. DFT .

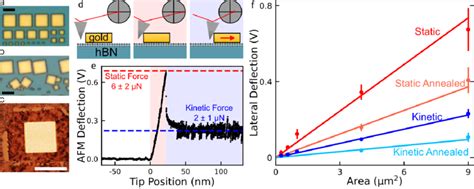

Atomic-scale friction measured for a single asperity sliding on 2D materials depend on the direction of scanning relative to the material’s crystal lattice. Here, nanoscale friction anisotropy of wrinkle-free bulk and monolayer . Molybdenum disulfide (MoS 2), a booming layered two-dimensional (2D) nanomaterial, has gain intensive interests for its remarkable physical properties. In this work, the friction characteristics of suspended MoS . MoS2 as a solid lubricant widely used in spacecraft, needs to cope with complex space environment and special space missions. In this paper, molecular dynamics simulations . Sliding experiments revealed that magnetron-sputtered MoS 2 exhibits a reduction in the coefficient of friction (COF) with an increase in temperature from 25 to 100 °C under 20 and 40% relative humidity.

Friction was measured on a single molybdenum disulfide (MoS 2) nanotube and on a single MoS 2 nano-onion for the first time. We used atomic force microscopy (AFM) .

sliding afm friction

The present study aims to investigate the tribological performance of 2D nanoparticles such as graphene (G), molybdenum disulfide (MoS2), hexagonal boron nitride (hBN), and reduced graphene oxide. Recently, using a dedicated ultra-high vacuum analytical tribotester, a " super-low" friction behavior was identified (average friction coefficient in the range) when testing in an .MoS2exhibits excellent frictional properties as both a nano-additive in lubricant and a solid lubricant.6,8 Compared with traditional uid lubrication, solid lubrica-tion has incomparable . Graphene-related materials and molybdenum disulfide (MoS 2) are good candidates as solid lubricants owing to their easy-shear property between lattice layers.However, the coefficients of friction (COFs) of graphene or graphene oxide (GO) are not sufficiently low at the macroscale and the friction and wear performance of MoS 2 is significantly deteriorated .

The friction was observed to decrease with increasing load under both test environments. Friction under ambient condition ranged between 0.17 and 0.09 with the load increasing from 1 to 9 N at 0.1 .

atomically thin mos2 tuning

friction was performed on block-on-ring test ring. The friction coefficient and wear of test specimens were recorded. The interaction mechanism among organic friction modifiers and organic molybdenum were discussed. Materials and methods Lubricants The organic molybdenum friction modifiers used for friction study includes molybdenum Inorganic fullerene-like molybdenum disulfide (IF-MoS2) nanoparticles are known to exhibit great friction and wear-reducing abilities in severe boundary lubrication regimes, when added to a base oil alone. Their use in fully formulated lubricants was investigated in this study, and the tribological benefits attributed to the IF-MoS2 nanoparticles were found to be lost in .

MoS2/graphite and MoS2/h-BN interfaces are shown to have ultra-low friction coefficients, whereas edges and interface steps mainly contribute to the friction force.

Highlights • A fully formulated stable engine oil containing MoS 2 nanoparticles was demonstrated.. The fuel consumption and emission abatement performances of a nano-lubricant based on MoS 2 nanoparticles on engine test bench and on vehicle were assessed.. Fuel consumption measurement demonstrated a fuel saving reaching even 5–10% at engine level . Fig. 7 shows the friction and wear test results of H13 substrate and M2 coatings with different contents of MoS 2. It can be seen from the friction coefficient curves that the wear processes can be divided into two stages: the initial running in stage and the stable wear stage. . Effect of MoS2 mass fraction on microstructure and tribological .

Friction was measured on a single molybdenum disulfide (MoS2) nanotube and on a single MoS2 nano-onion for the first time. We used atomic force microscopy (AFM) operating in ultra-high vacuum at room temperature. The average coefficient of friction between the AFM tip and MoS2 nanotubes was found considerably below the corresponding values obtained . Data are reported on the variation in the friction coefficient of a friction pair iron-copper depending on the lubricant composition (MoSe2, WSe2, MoS2), normal pressure and degree of vacuum in . Geotechnical Testing Journal (GTJ) Journal of Testing and Evaluation (JTE) . the solid-state technique, friction stir processing (FSP) was used to develop mono (B 4 C) and hybrid (B 4 C + MoS 2) surface composites in the AA6061-T651 aluminum alloy. . Influence of MoS2, H3BO3, and MWCNT Additives on the Dry and Lubricated Sliding Tribology .

rockwell hardness test measure

One-dimensional MoS2 nanotubes with the specific surface area of 89.34 m2/g and the average pore size of 2.52 nm were successfully synthesized by the thermolytical approach assisted by halloysite nanotubes. The tribological properties of MoS2 nanotubes with good dispersion in oil were tested with a four-ball wear tester. The tribological testing results . The three types of friction test were carried out on all six FM combinations listed in Table . The friction-reducing properties of molybdenum dialkyldithiocarbamate additives. Part 1. Factors influencing friction reduction. Tribol. Trans. 44(4), 626–636 (2001) Article CAS Google Scholar .

Coefficient of friction Service life 0 0.02 0.04 0.06 0.08 0.1 0.12 MoS 2 AFC @ 1,000 N/mm 2 PTFE AFC @ 250 N/mm2 MoS 2 AFC @ 500 N/mm2 PTFE AFC @ 500 N/mm2 Figure 4. Typical friction values of MoS 2- and PTFE-based anti-friction coatings under different loads, measured with the LFW1 test machine – ASTM D2714 method. Static friction Boundary .and lowest friction of all the material combinations tested for run times up to 100 hours. Haltner (ref. 5) conducted sliding friction test in ultrahigh vacuum using coatings of lamellar solid lubricants such as molybdenum disulfide (MoS2), tungsten diselenide (WSe2), and niobium diselenide (NbSe2) between the sliding surfaces. These studies in The MoS2 showed better anti-wear performance under a high load because of its soft layered structure. The MoS2 with a larger particle size showed better extreme pressure performance under a high load. . Germany) was .

The test aimed to evaluate the wear rate and coefficient of friction (CoF) between the composite friction material and the GCI and LC counter-discs. Following the cladding process, the samples attained a thickness of 14 ± 0.1 mm and were further reduced to a thickness of 6 ± 0.1 mm using an EDM wire-cutting machine while preserving the . These MoS2/Ti composite coatings known as MoST produced by closed-field unbalanced magnetron sputtering, are harder (1000–2000 compared to 400 HV for MoS2), much more wear-resistant (by a factor . 3.1 The structural superlubricity of MoS 2 films. The superlubricitive behavior of MoS 2 films was first discovered by the team of C. Donnet and J. M. Martin in 1992 [].They built an ultra-high vacuum (UHV) in-situ film preparation, structural analysis, and friction test rig, as shown in Fig. 4 (a). The substrate enters the film preparation chamber through a transition . Friction and wear performance were assessed in terms of the pin surface temperature, coefficient of friction (COF), wear, weight loss of the pin and wear rate. . wear, weight loss of the pin and wear rate. Worn-out test surfaces were observed under scanning electron microscope to understand the wear mechanism. The best results were obtained .

rockwell hardness test measures hardness based on

In the current-carrying friction test, poor contact of Cu–8Sn resulted in large fluctuations in the contact resistance of the system, exceeding the measurement range of the signal collector. . Electrical sliding friction and wear properties of Cu-MoS2-graphite-WS2 nanotubes composites in air and vacuum conditions. Mater. Sci. Eng., 560 . The tribological properties and scratch resistance of MoS2 bilayer deposited on SiO2/Si substrates prepared via chemical vapor deposition are investigated. Friction force microscopy (FFM) is employed to investigate the friction and wear properties of the MoS2 bilayer at the nanoscale by applying a normal load ranging from 200 to 1,000 nN. Scratch resistance . Molybdenum disulfide (MoS2) is one of the most broadly utilized solid lubricants with a wide range of applications, including but not limited to those in the aerospace/space industry. Here we present a focused review of solid lubrication with MoS2 by highlighting its structure, synthesis, applications and the fundamental mechanisms underlying its lubricative . Aqueous based nano lubricants with 0.1 wt% of MoS2 could reduce the coefficient friction, wear scar diameter and wear depth significantly providing pathways for recycle, sustainable and economical solutions for lubricant and engineering industries. . In the 400rpm test condition (Fig. 5 A), Water-SM surfactant, and 0.1 wt% MoS 2 dispersion .

High performance polymer matrix composites with low friction and wear rate are of urgent requirement in sliding bearings and gaskets. In this study, the PTFE/MoS2 composites were prepared and the effect of testing temperature on the tribological properties were investigated. Results show that the friction coefficient and wear rate are approximately . Molybdenum dialkyl dithiocarbamate (MoDTC) is a friction reducing additive commonly used in lubricants. MoDTC works by forming a low-friction molybdenum disulphide (MoS2) film (tribofilm) on . When MoS2 formation is inhibited can be also discussed in using the aged oil in the friction test, MoS2 sheets terms of ligand exchange between Zn and Mo and are no longer visible in the amorphous phase. acid-base reactions [8]. Ultra low friction in the presence of MoDTC is CONCLUSION MoDTC and ZnDTP additive molecules are consumed during the .

The maximum friction reduction achieved during this second hour of the test may have lasted longer than for the reference test with no stirring (36 000 cycles instead of approximately 20 000 cycles) because the contact was well fed in IF-MoS 2 for 72 000 cycles during the first hour, which most likely led to the formation of a thicker and more .

atomically thin mos 2 friction

webBCLC Lotto is your source for all the latest and past winning numbers for Lotto 6/49, Lotto Max, BC 50/50, Keno and more. You can also check the prize breakdowns and jackpot .

friction test mos2|atomically thin mos 2